Types of printing methods

A Guide For Packaging And Design

Printing is an essential aspect of packaging and design. It’s how you bring your ideas to life, make your product stand out on the shelf, and communicate your brand.

Printing Methods for Packaging and Design

With so many printing methods available, knowing which is best for your project can be challenging. We’ll take a closer look at the most common printing methods and their advantages and disadvantages so that you can make an informed decision regarding your packaging and design needs.

Printing Methods for Packaging and Design

There are many different printing methods available. Choosing the right one depends on several factors, including the product type, the material you’re printing on, and the desired outcome. Some of the most common printing methods for packaging include:

Offset Printing

A traditional printing method using large printing presses. This form of printing involves transferring an image from a metal plate to a rubber blanket and then onto the printing surface. The metal plate is etched with the desired image or text, and then ink is applied to the plate.

Suitable for:

Large runs, and it’s an efficient and cost-effective option for printing high-quality images and text.

Digital printing

This is a newer printing method that uses digital technology. It’s a fast and flexible option, as you can change your design until the printing process begins. Digital printing provides the full-colour spectrum, cost-effective, and is highly versatile.

Suitable for:

Small runs and is an excellent option for printing high-quality images, text, and photos.

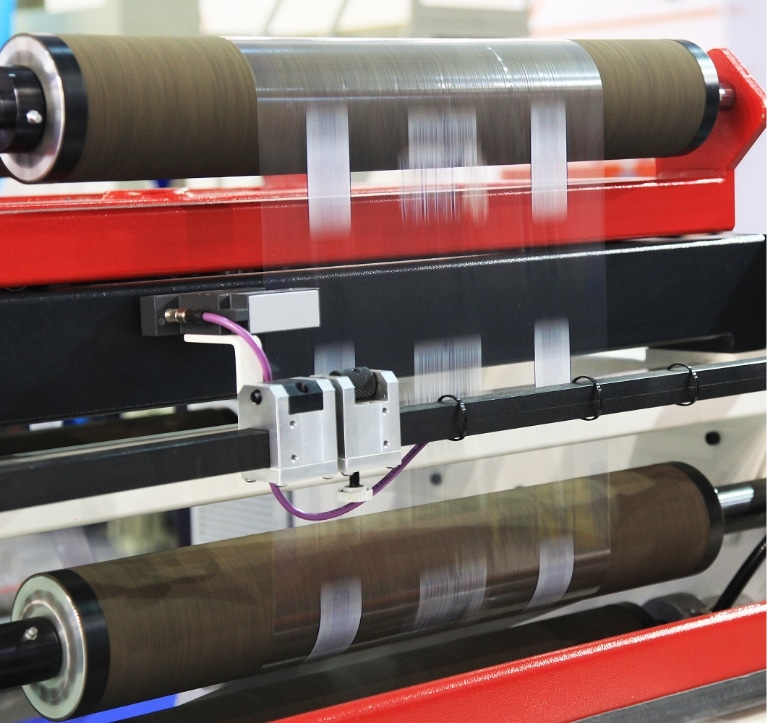

Flexography

This printing method is commonly used for printing on flexible materials such as plastics and cellophane. This printing method uses flexible relief plates to print on a variety of materials, including paper, plastic, and metal. The plates are made from a flexible material, such as rubber or polymer, and are wrapped around a rotating cylinder.

Suitable for:

Printing on various materials and allows for more ink types to be used than traditional digital printing.

Interested In Finding The Right Printing Method For Your Business?

Advantages and Disadvantages of Different Printing Methods

Advantages

Offset Printing

Often used for magazines, brochures, and newspapers.

Offset printing can produce high-quality printing at scale, making it a very popular choice for businesses requiring a high level of detail and colour accuracy.

Efficient production times: Offset printing can produce high volumes of prints quickly and efficiently, making it an ideal choice for large print runs.

Cost-effectiveness for large runs: Offset printing is a cost-effective method for producing large print runs, with average cost decreasing as the number of pages increases.

Digital Printing

Often used for a variety of materials, including paper, plastic, and fabric.

Digital printing allows for fast and flexible printing without printing plates and the setup time required.

High-quality printing: Digital printing can produce high-quality output with sharp images with a high level of colour accuracy.

Design flexibility: With digital printing, you can make changes to your design until the printing process begins.

Flexo Printing

Often used on cardboard boxes, paper bags, and plastic films.

Flexography is a high-speed printing method that can produce large print runs quickly and efficiently.

Cost-effectiveness for large runs: Like offset printing, flexography is a cost-effective method for producing large print runs, as average cost decreases as the number of prints increase.

Ability to print on various materials: Flexography is a versatile printing method that can be used to print on a variety of materials, including paper, plastic, and metal.

Disadvantages

Offset Printing

Often used for magazines, brochures, and newspapers.

Offset printing may not be as cost-effective for smaller print runs due to the initial setup and plate-making costs.

Once the printing plates are made, it can be difficult to make changes to the print design. Making it less flexible than digital printing methods.

Digital Printing

Often used for a variety of materials, including paper, plastic, and fabric.

Digital printing can be more expensive per unit than other traditional printing methods.

Digital printing is not always suitable for all materials, and certain substrates may require specialised inks and equipment to print on.

Flexo Printing

Often used on cardboard boxes, paper bags, and plastic films.

Flexography requires specialised equipment, including a printing press and printing plates, which can be a significant investment for small businesses

Once the printing plates are made, it can be difficult to make changes to the print design, making flexography less flexible than digital printing methods.

In Summary

Choosing the Right Printing Method for Your Project

Many different printing methods are available, each with unique strengths and benefits. From traditional printing methods such as letterpress to modern digital printing techniques, the right printing method for you will depend on your specific needs and requirements.

So why not contact us today and discover how we can help you get the results you're looking for?